- COPPER UPWARD CAST

- CU & AL EXTRUSION

Continuous Extrusion Production Line for Copper Profiles

Continuous Extrusion Production Line for Aluminum Profiles

Combined Type Cu/ Al Profiles Continuous Extrusion Line

Hydraulic Drawing Machine for Copper /Aluminium Busbar

Fully Automatic Hydraulic Drawing/Straightening/Cutting Line

- ROLLING MILL

- ANNEALER

- CONVERT WIRES

- WIRE DRAWING

- WIRE/CABLE PROCESS

- AUXILLARIES

- BRIEF INTRODUCTION

- GALLERY

- MULTIMEDIA

-

I. Introduction

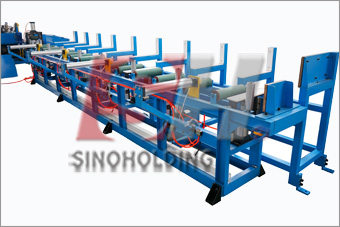

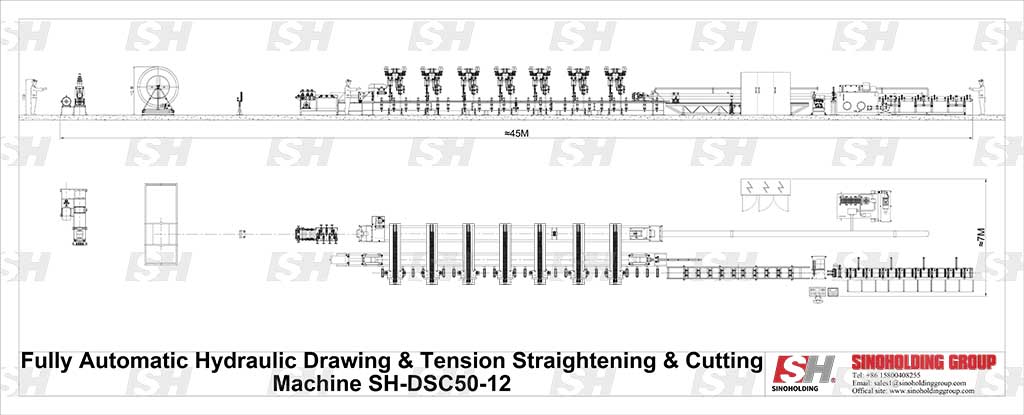

Fully Automatic Hydraulic Drawing & Tension Straightening & Cutting Machine is mainly used for drawing copper or aluminium profiles made by continuous casting machine, aiming to improve the dimensional accuracy, surface finish, hardness, elastic limit and conductivity of the product. Compared with the traditional drawing machine, the tension straightening machine and the automatic cutting machine are added, which can better improve the product quality, improve the production efficiency and save the labor cost. It is the drawing equipment with the highest level of technology, productivity and automation in China and abroad.

II. Technical characteristics

It adopts a new type of transfer trolleys and high-speed transfer arms, it can realize a timely product transfer after the finish of each step of drawing, straightening and feeding. An uninterrupted operation of the production line can be ensured, because the speed of the transfer arm is higher than that of drawing, straightening and feeding.

After the above steps, the copper busbar is automatically fed by the fully automatic feeding, cutting and storage line, the length is cut within an error of 1mm and stored for the next step. The operator only needs to input the figure and length of the copper busbar on the touch screen. It is easy to ensure a fully automatic operation of the entire production line.

The so-called fully automatic production line of the general manufacturer still uses the manual controlled cutting machine to realize the sawing, the cutting length precision is poor, the copper busbar length is difficult to guarantee, the incision is not uniform, possibility of influence from human is high and so on, all of them further reduce the working efficiency of the production line.

III. Technical characteristics

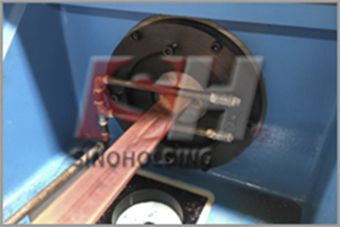

By improving the hydraulic system, the drawing speed, the return speed of the cylinder and the drawing force are greatly improved. When the width of the drawn copper bar is less than 100MM, two copper bars can be drawn at the same time, thereby greatly improving the production efficiency of the machine.

IV. Equipment major components

V. Main technical parameters

Model

SH-DSC50

SH-DSC100

Effective drawing length(m)

6~12

6~12

Nominal drawing force(t)

50

100

Profile specification (mm)

Width

30~170

50-350

Thickness

3~30

5-35

Drawing speed (m/min)

3~15

3-12

Return speed (m/min)

35-40

30-35

Hydraulic station oil pressure(mpa)

10-15

10-15

Main motor power(kw)

120

135

Tension Straightening force (mpa)

50

100

Automatic cutting and fixed length range(m)

0.5-6

0.5-6

Automatic cutting Precision(mm)

0-3

0-3

Sawing model

Hydraulic

Related suggestion:Copper StripsCopper Bus-bars

-

-

>>>>>> Youtube

- You are here:

- Home

- > WHAT WE DO

- > CU & AL EXTRUSION

SINOHOLDING GROUP CO.,LTD

Head office:

Room 1610, 3F, No. 277, Zheqiao Road, Jinqiao, Pudong New Area, Shanghai, China.

Mob:+86 158 0040 8255 (Viber, WhatsApp)

Email:sales1@sinoholdinggroup.com

Anhui office

No. 2, Guohua Road,Pingqiao industry park, Luan city, Anhui province, China.

Tel:+86 151 5521 0552