- COPPER UPWARD CAST

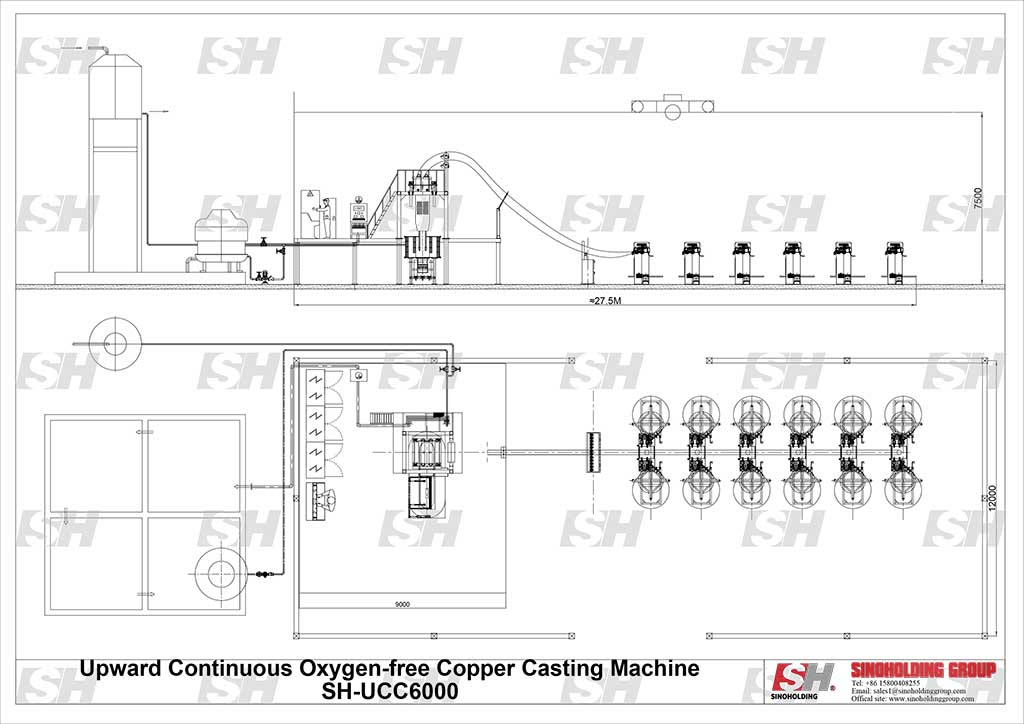

Upward Continuous Oxygen-free Copper Casting Machine

High Quantity Upward Continuous Copper Rod Casting Machine

Upward Oxygen-free Cu[Cu(Mg), Cu(Ag)] alloy rod Caster

- CU & AL EXTRUSION

- ROLLING MILL

- ANNEALER

- CONVERT WIRES

- WIRE DRAWING

- WIRE/CABLE PROCESS

- AUXILLARIES

- BRIEF INTRODUCTION

- GALLERY

- MULTIMEDIA

-

I. Introduction :

Upward Continuous Oxygen-free Copper Rod Casting Machine is used for producing long bright oxygen-free copper rod. The raw material can be cathode or high grade scrap, through continuous up-casting into various specifications copper products. This equipment adopts advanced technology and environmental-friendly. The oxygen-free copper rods and copper profiles produced by the machine have many advantages for example, extremely high conductivity, low oxygen content and etc..

II.Equipment major components and description :

1)Copper melting furnace

The combined induction furnace is designed by the principle of electromagnetic induction. The current passes through the resistance of the metal furnace charge to convert the electrical energy into heat energy and which melt the metal in the molten groove. The induction furnace adopts a structure that metal smelted and insulated in one furnace, with a partition wall in the middle and an flow passage at the bottom.

2)Upward continuous casting machine

It adopts a servo motor and which matches with the high-precision reducer to adjust the lifting and up-casting speed of the copper rod.

The servo motor transmits the power to the main drive shaft through the high-precision reducer, the main drive shaft pulls the copper rod. The pull-stop-reverse parameters can be set arbitrarily through the touch screen and PLC. A continuous copper water level tracking system is installed on the continuous casting machine and it is driven by an independent AC motor.

The copper rod clamping method is pneumatic and the crystallizers can be quickly lifted in an emergency state.

3) Take-up limit tension frame

The intermittent work of take-up motor is controlled by the tension of the copper rod.

4)Dual take-up machine

The take-up machine controls the frequency converter by the limit device to realize the synchronization of the up-casting and take-up speed and automatically collects the copper rod into the take-up platform..

5) Electrical control system

The electric control system consists of a set of induction furnace electric controlcabinet and a set of continuous casting machine electrical control cabinet.

The servo motor adopts Yaskawa product from Japan, the PLC adopts Mitsubishi product from Japan and the electrical components of induction furnaces are Schneider from France.

6) Temperature monitoring system

The equipment uses a high-precision intelligent temperature sensor to monitor the copper temperature inside the furnace, the total inlet water temperature and the water temperature of each outlet pipe to monitor the crystal quality of the copper rod and the operation of the induction furnace.

7) Water-cooling system

The water cooling system can be provided by the customer or provided by SINOHOLDING additionally. It is required to provide soft water with a pure water temperature of 35 Celsius (plus or minus 5 Celsius).

III. Techinical parameters

Model

No. of strands

Product size

Furnace type

Annual production

Consumption ( kwh/t )

SH-UCC1000

2

Φ8-Φ25mm Single furnace

1000t ≤350 SH-UCC2000 4 Φ8-Φ25mm Three-combined furnace

2000t ≤350 SH-UCC3000 6 Φ8-Φ25mm Three-combined furnace 3000t ≤350 SH-UCC4000 8 Φ8-Φ25mm Three-combined furnace 4000t ≤350 SH-UCC5000 10 Φ8-Φ25mm Three-combined furnace 5000t ≤350 SH-UCC6000 12 Φ8-Φ25mm Three-combined furnace 6000t ≤350 SH-UCC7000 14 Φ8-Φ25mm Three-combined furnace 7000t ≤350 SH-UCC8000 16 Φ8-Φ25mm Five-combined furnace

8000t ≤350 SH-UCC9000 18 Φ8-Φ25mm Five-combined furnace

9000t ≤350 SH-UCC10000 20 Φ8-Φ25mm Six-combined furnace

10000t ≤350 SH-UCC12000 24 Φ8-Φ25mm Six-combined furnace

12000t ≤350 Related suggestion:Copper StripsCopper Bus-bars Copper WiresRailway Contact Wires / Load-Bearing Cables

-

-

>>>>>>Click to get video

- You are here:

- Home

- > WHAT WE DO

- > COPPER UPWARD CAST

SINOHOLDING GROUP CO.,LTD

Head office:

Room 1610, 3F, No. 277, Zheqiao Road, Jinqiao, Pudong New Area, Shanghai, China.

Mob:+86 158 0040 8255 (Viber, WhatsApp)

Email:sales1@sinoholdinggroup.com

Anhui office

No. 2, Guohua Road,Pingqiao industry park, Luan city, Anhui province, China.

Tel:+86 151 5521 0552